News

How technology is revolutionising footwear components

In recent times, footwear components have undergone a significant transformation thanks to technological advancements. Innovations such as high-frequency technology, the use of sustainable materials, and digital printing, among others, are redefining the manufacturing and functionality of modern footwear.

Technological innovations in footwear components

At BRITIGRAF, we use advanced technologies to manufacture footwear components, ensuring high-quality and customized products according to our clients’ needs. Our main techniques include:

- Microinjection: We use Bio Plastisols to create high-definition and flexible embellishments and labels. This technique allows for combining different heights, textures, and colors in the same embellishment, applicable on various materials.

- Thermoplastic injection: We manufacture technical pieces such as eyelets, lace loops, and rings using materials like TPU, PVC, SBS, nylon, and ABS. This process enables us to offer screen-printed, aged, inserted, and metallic finishes, adapted to different sectors such as footwear, furniture, and automotive.

- High-frequency technology: Using high-frequency waves, we produce embossed decorations and shapes applied to labels and shoe parts, such as toe caps and straps. This technique allows for combining different colors and materials like leather, neoprene, and reflective fabrics, adding originality and personality to brands.

- Screen printing: We apply inks directly onto various materials, known for their high quality and speed. This technique is ideal for embellishments, insoles, and labels, offering a wide range of colors and finishes.

- Stamping and engraving: We use processes such as transfer, pad printing, hot stamping, and burning to apply finishes on leather, fabrics, and synthetics, mainly on insoles and shoe parts. Each technique is adapted to the client’s style and needs.

- Digital printing: We have digital printing machines using eco-solvent and UV LED ink, allowing printing on a wide range of materials such as leather and synthetics. This technology offers great adhesion and high-quality finishes.

These technologies allow us to offer innovative and sustainable solutions in the manufacturing of footwear components, adapting to market trends and our clients’ demands.

What types of footwear components do we manufacture at BRITIGRAF?

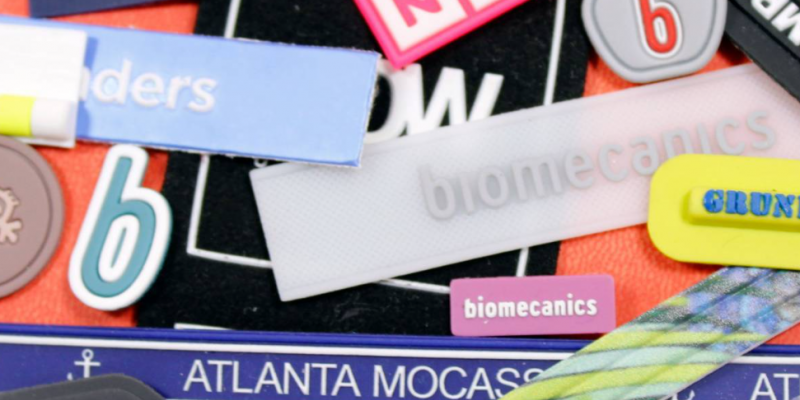

At BRITIGRAF, we specialize in producing footwear components that combine quality and advanced technology. Our catalog includes:

- Embellishments and labels: Manufactured using microinjection, injection, and high-frequency techniques, ideal for customizing and enhancing footwear.

- Insoles: Developed with materials that offer optimal pressure distribution and excellent shock absorption, improving user comfort.

- Soles and heels: Produced with durable materials and innovative designs that ensure both resistance and style.

Each of our products is designed to meet the specific needs of our clients, guaranteeing personalized and high-quality solutions.

At BRITIGRAF, we are defined by our commitment to excellence in footwear component manufacturing

With over 40 years of experience in the footwear component manufacturing industry, BRITIGRAF stands out for:

- Constant innovation: We incorporate the latest technologies into our manufacturing processes to offer cutting-edge products.

- Personalized service: Our team of professionals is dedicated to understanding and meeting each client's unique needs.

- On-time delivery: We value your time, so we guarantee punctual deliveries without compromising on quality.

If you're looking for footwear components that add value and distinction to your products, don’t hesitate to contact us!

- Email: info@britigraf.com

- Phone: +34 965 683 882

- Facilities: Calle Alberto Sols, 18 – ELCHE PARQUE EMPRESARIAL - 03203 Elche (Alicante), Spain.